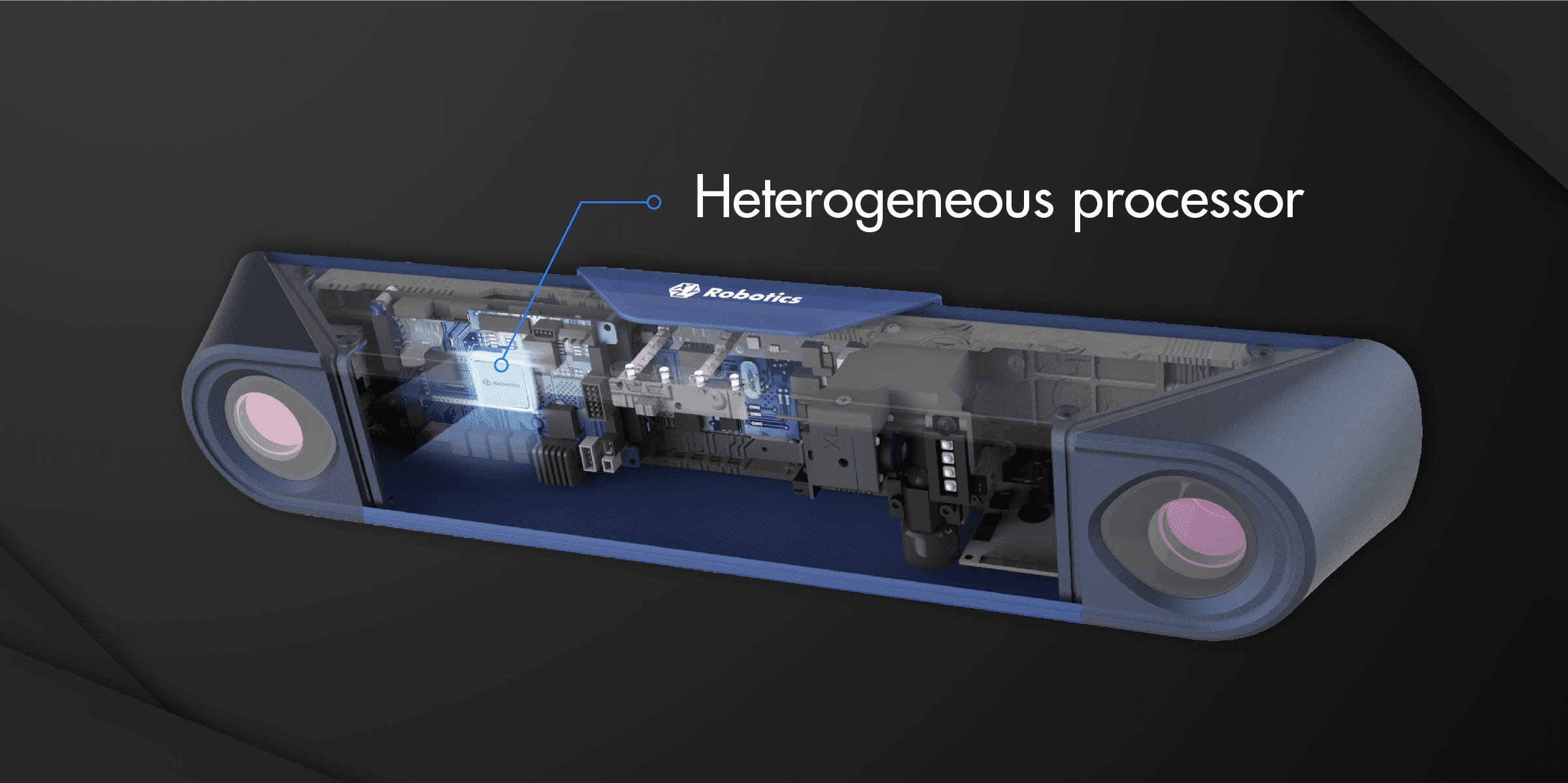

XYZ Robotics has enhanced LS-XL Laser Structured Light 3D Camera with faster imaging capability. Compared to its previous version, LS-XL camera adopts a powerful heterogeneous processor, which increases the imaging speed by 58%.

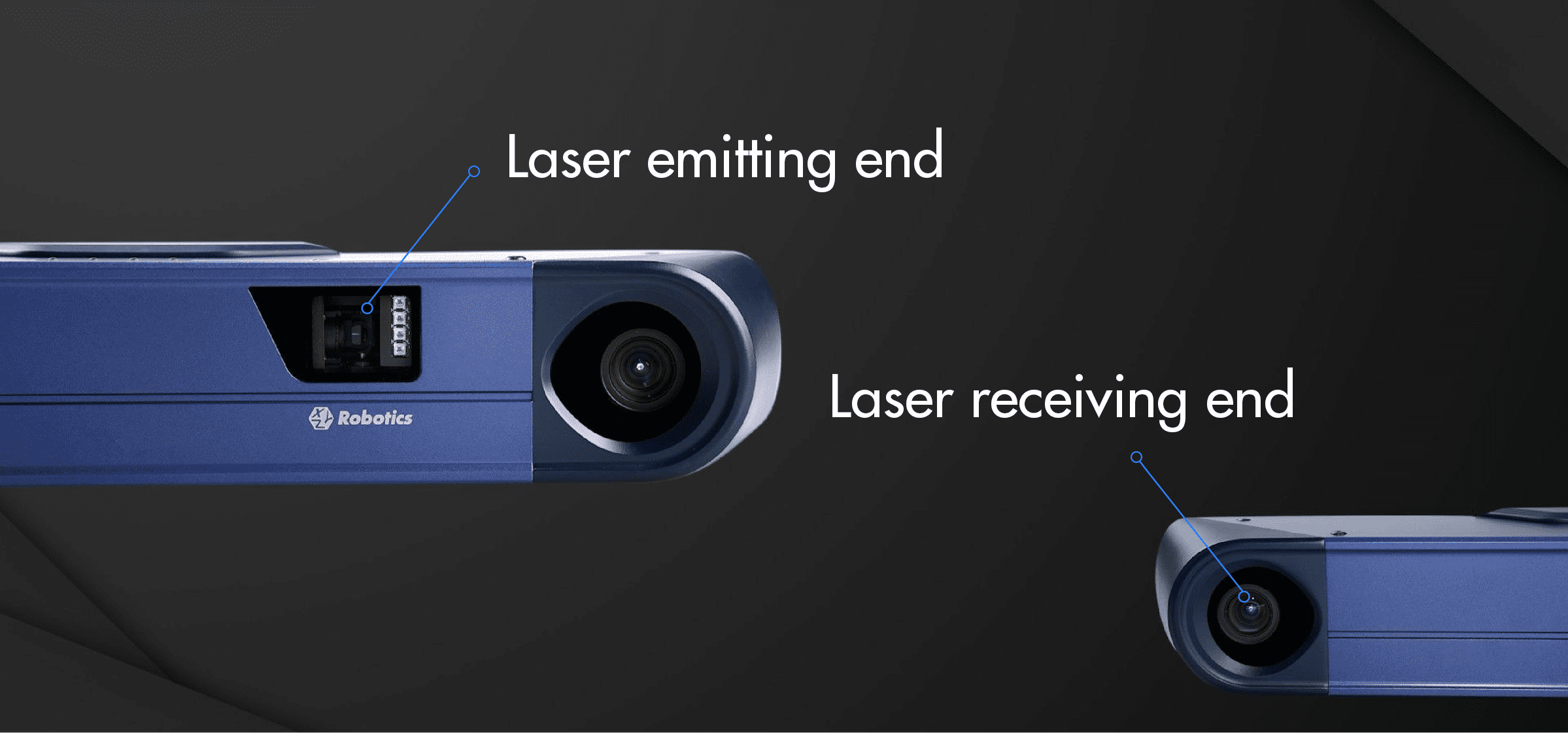

LS-XL camera is a member of our Structured Light Camera Series. The camera projects a high-power red laser from the emitting end and generates structured light through the galvo. The structured light is penetrating enough for effective imaging in conditions of low light, strong ambient light, and a long distance.

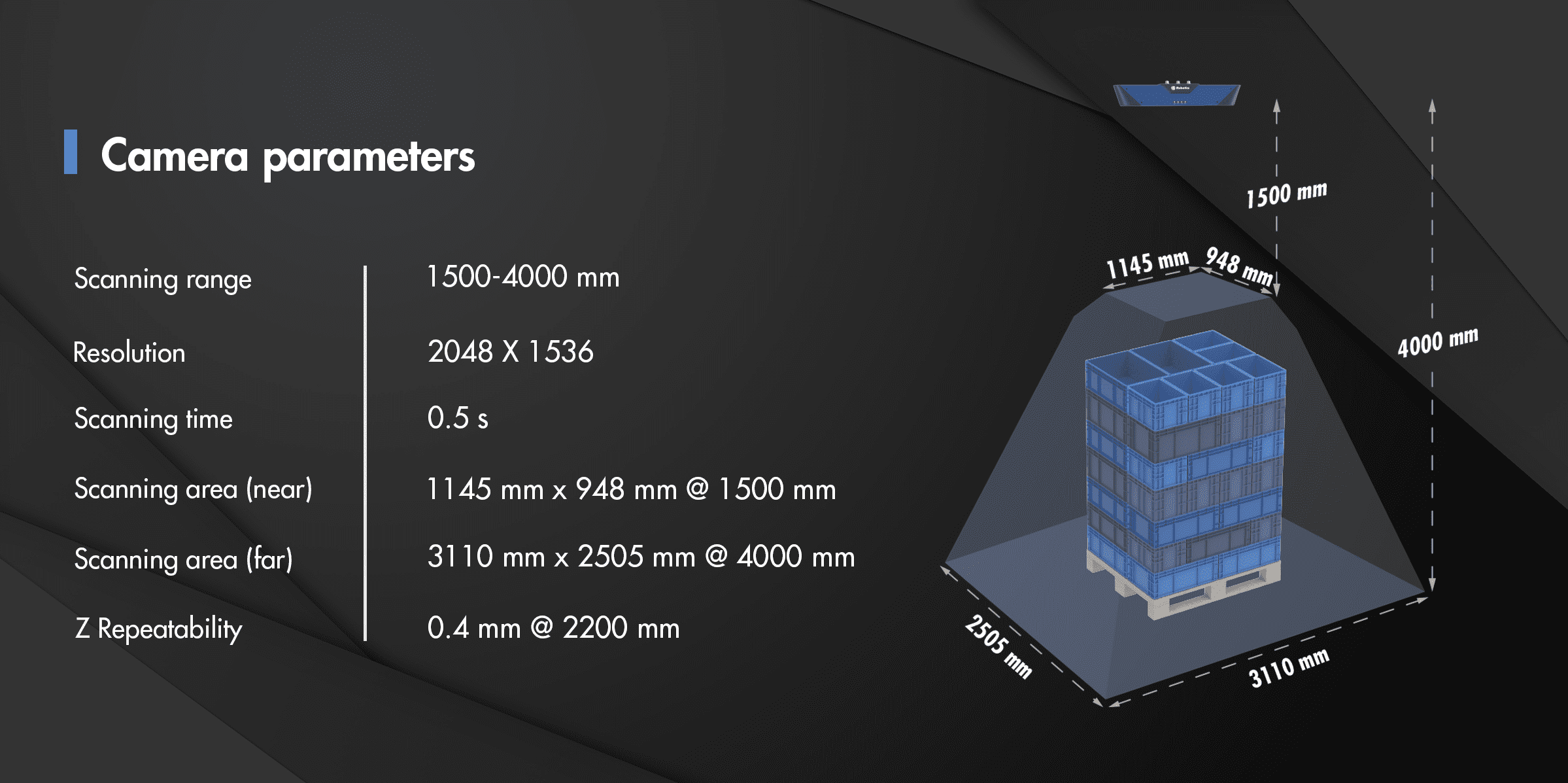

New LS-XL camera not only enables fast imaging in just 0.5 seconds but also features a large Field of View (FOV) and ambient light resistance. Designed for a scanning range from 1.5 to 4 meters, LS-XL camera excels in long-distance conditions and covers a wide range of potential applications.

Its exceptional ambient light resistance capability (28000 Lux @ 1.5 m) ensures strong performance even in sunlit areas and bright workshops.

LS-XL camera is suitable for logistics scenarios requiring high recognition accuracy, such as thin-framed tote (de)palletizing and mixed case depalletizing. In addition, it is competent for industrial applications such as random bin picking. Incorporating an IP65 protection class, the camera ensures stable operation even in harsh conditions.

Case Study

Challenges:

The automotive industry requires inbound and outbound automation that coordinates seamlessly with automotive part manufacturing. The thin-framed tote is a common storage unit for automotive parts. These totes are of various dimensions and easy to deform. Moreover, totes are usually stacked high to optimize storage space. Therefore, accurate picking of these totes poses significant challenges to both camera’s field of view and its precision.

Our solutions:

- Accurate recognition: Equipped with the model matching algorithm, the high-precision LX-XL camera accurately recognizes different types of totes in various poses.

- Great throughput: LS-XL camera enables fast imaging in just 0.5 seconds, which leads to an overall throughput of up to 500 cases/hour.

Challenges:

An international automotive supplier requires 3D vision-guided feeding of black billets. The robot needs to pick black billets and place them on the downstream machine tool automatically. Black billets are closely piled in cluttered bins. These billets come in various specifications and have poor consistency.

Our solutions:

- Adapt to dark surfaces: LS-XL camera, paired with deep learning segmentation and point cloud matching algorithm, can accurately recognize closely arranged black billets (precision: ±1.5 mm).

- Efficient layer-wise recognition: Utilizing the point cloud height segmentation method, LS-XL camera can recognize only the top-layer parts and guide collision-picking in the absence of a divider. The vision recognition cycle time is ≤ 4 s/piece.

As the latest chapter in the ongoing development of XYZ’s industrial 3D cameras, the upgraded LS-XL camera impresses with large FOV, ambient light resistance, and fast imaging. When paired with our latest 3D vision software XYZ Studio Max, it offers a seamless and exceptional 3D vision experience.

United States

United States