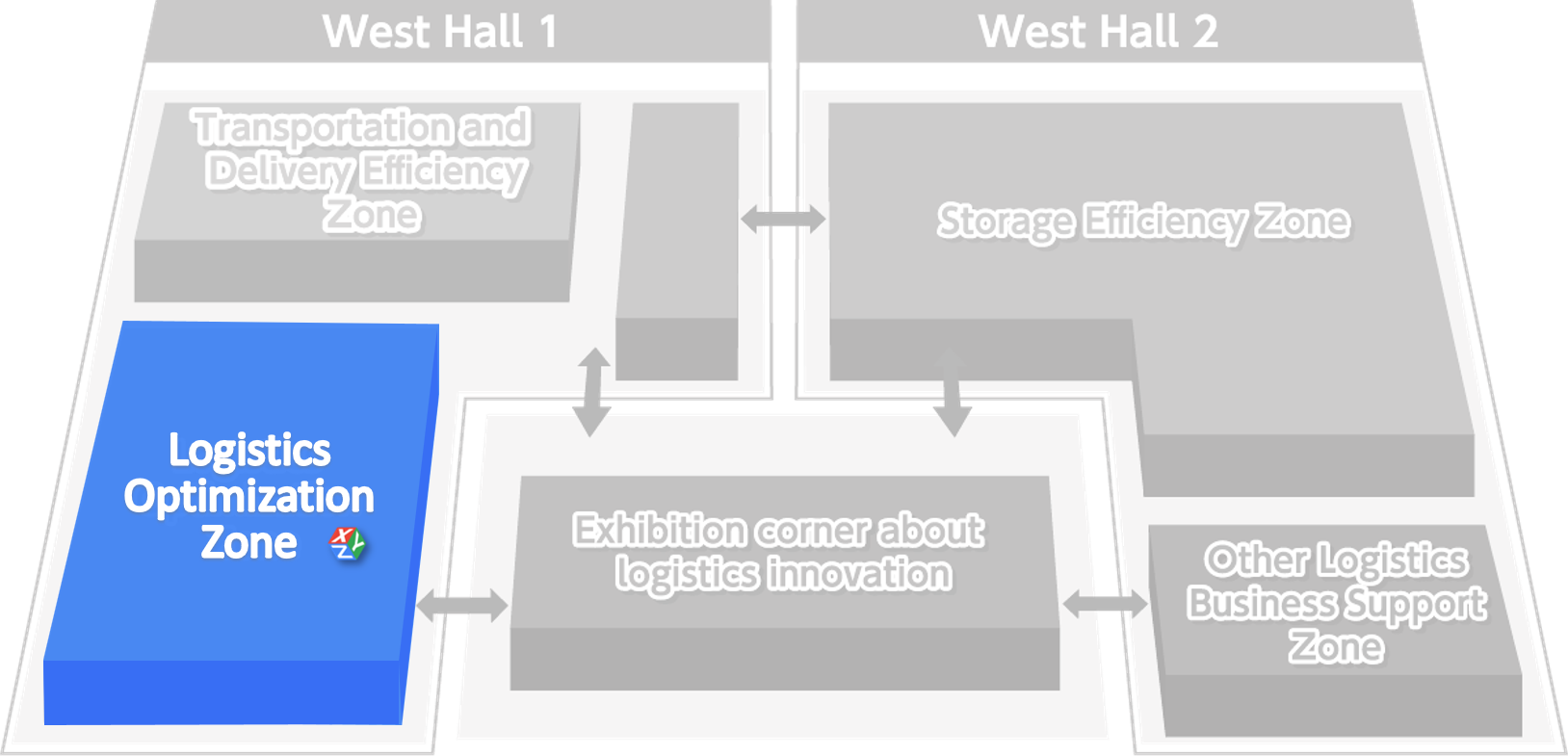

From September 13th to 15th, XYZ Robotics will show up at Japan's largest logistics exhibition Logis-Tech Tokyo 2023 at Tokyo Big Sight. Visitors to Booth 1C-05 will experience the only Robotic Trailer (Un)loading Solution showcased at the exhibition.

Trailer (Un)loading Solution

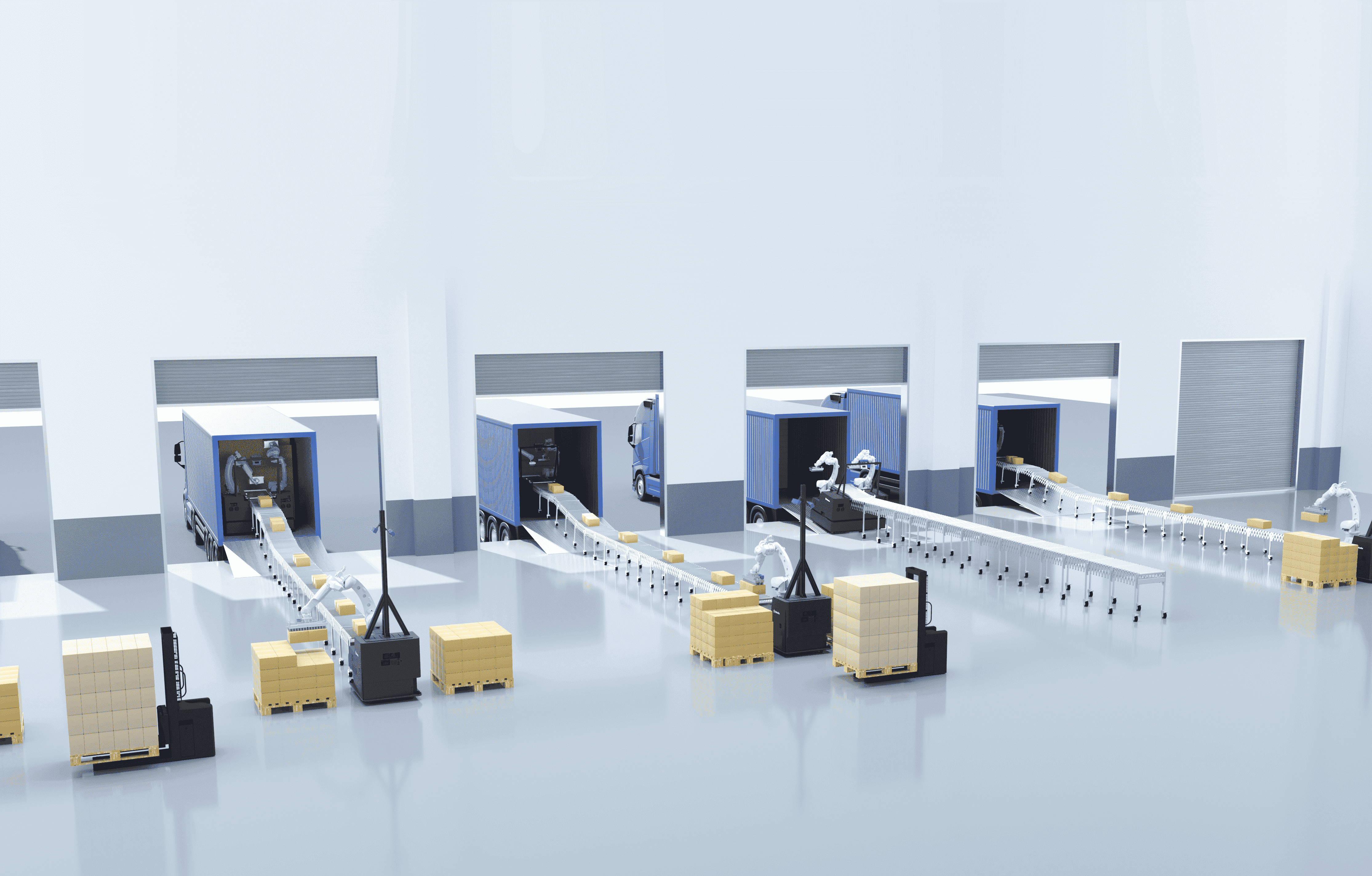

In the realm of intralogistics material handling, trailer (un)loading is predominantly carried out manually. Existing robotic picking solutions have yet to address this specific area. However, the manual method is costly, inefficient, and poses significant safety risks to workers who lift and move heavy cases. Therefore, there is a surging need for automated solutions.

Through remote control, XYZ Robotics' Trailer (Un)loading solution achieves fully automated material handling and frees workers from heavy lifting as well as injury risks. Besides, our solution emerges with several key benefits.

Easy to deploy

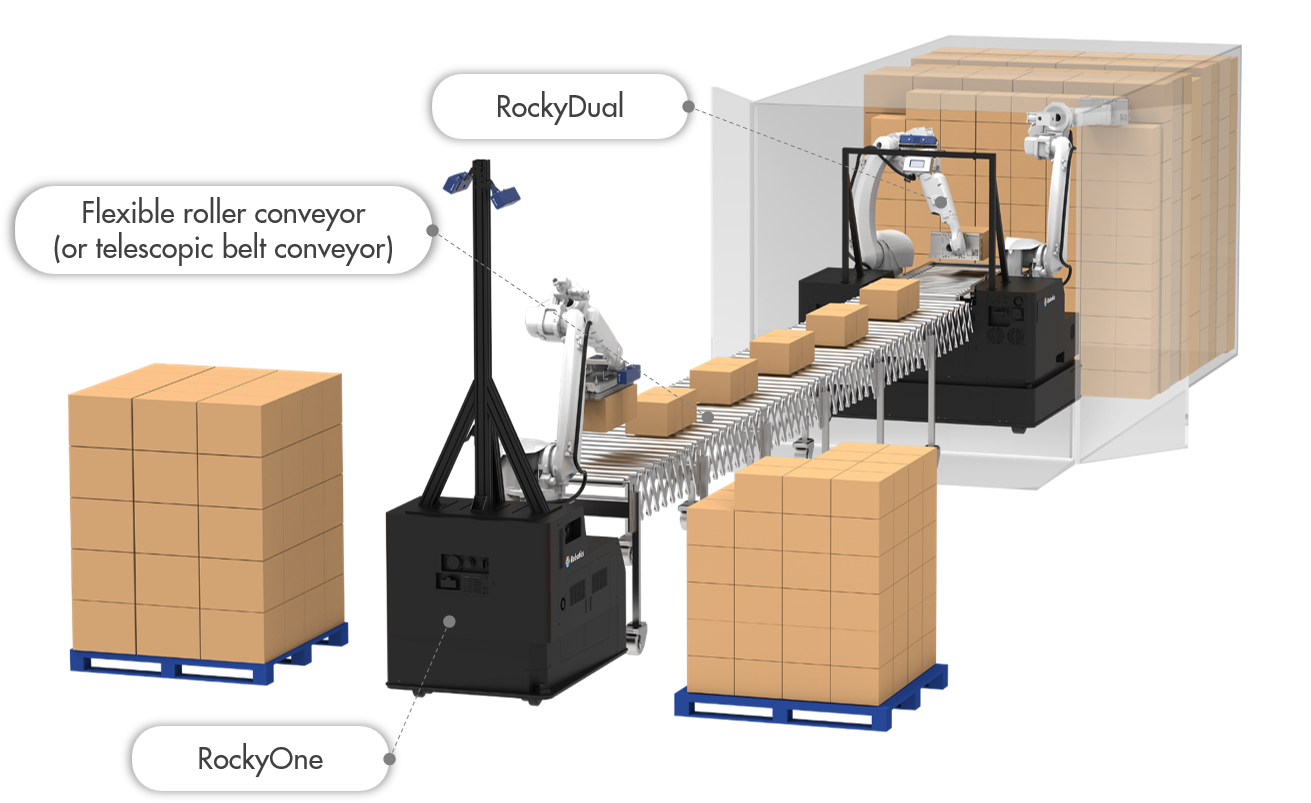

The solution comprises two mobile palletizers, RockyOne with one robot arm and RockyDual featuring two robot arms. Equipped with a mobile base, they can move to designated positions and start operations directly. The two robots also carry comprehensive components such as 3D cameras, vision software Studio Max, algorithms, and custom grippers, which enable them to work without additional infrastructure.

Confronted with a variety of incoming cases, the system operates without prior model registration. Our deep learning algorithm supports accurate recognition of unknown case types and allows instant depalletizing.

Flexible

Featuring mobility and a small footprint, the robots are flexible enough to adapt to different docks and warehouses. Given foreseeable order information, the robots can be added or removed to handle variable inbound traffic, making the solution highly scalable and customizable to meet different business needs. When not in use, they can be relocated to free up the dock space for other uses.

Efficient

Utilizing advanced robotic technology and perception algorithms, our solution excels at efficient picking operations, even in a compact layout. In a freight car with confined space, two robot arms of RockyDual collaborate seamlessly to pick 900 cases (up to 1200 cases) per hour.

With a fully charged battery, our robot can operate continuously for 8 hours. When plugged in for power, it can seamlessly cover multiple shifts while ensuring stable performance. This reliable and consistent operation makes our system particularly suitable for high-throughput warehouses.

XYZ Robotics in Japan

During our expansion journey, Japan has emerged as a crucial region for us. With its aging population, the logistics industry in Japan is facing a shortage of labor. This has created a significant demand for robotic automation solutions to fill the gap.

We have established a partnership with SoftBank Robotics and contributed to its Logistics Innovation Laboratory with our Mixed Case Palletizing Solution. Following this collaboration, we've also successfully implemented robotic picking solutions for Japanese businesses.

Recently, a leading Japanese 3PL server employed our vision-guided depalletizing and mixed case palletizing systems in a retail warehouse. Utilizing accurate vision recognition and advanced pallet planning algorithm, the robot systems can handle cases coming in a random order and achieve fully automated order picking. Paired with AS/RS and AMRs, our solution empowers a flexible and efficient outbound process, greatly reducing repetitive labor work.

United States

United States